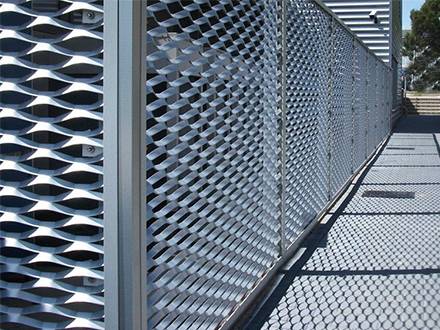

PVDF coated decorative expanded metal installed on top of office corridor

Expanded mesh ceiling for dining room

PVDF coated Expanded metal ceiling for lounge

Expanded metal mesh for conference hall ceiling

Expanded metal ceiling is one of indispensable materials in modern building design. It not only brings amazing visual effect, but also delivers fireproof, heat insulation, noise absorption and other practical functions. It is widely used in museums, places of assembly, sales areas, shopping centre, stadiums, banks, cinemas, theatre, assembly rooms, common rooms, facilities for meetings, conventions and conferences, offices, train stations, airports, hotels and resorts and other public buildings.

It is generally made of aluminum alloy plate and comes in a variety of hole patterns and sizes. Its powder coated, anodized or PVDF coated finish offers an attractive appearance with uniform color.

Whether for accent borders, clouds, or full ceilings, expanded metal panels are the excellent choice to enhance the visual appearance of the ceiling. The panel has elegant mesh configuration and can offer an aesthetically shading effect. Each panel can be individually operated, like tiled, swung down or slid for all your unique interior design. There are a variety of patterns and colors provide to help visualize your projects. However, if you cannot find the exact pattern you are looking for, we can manufacture tooling to meet your specific requirements.