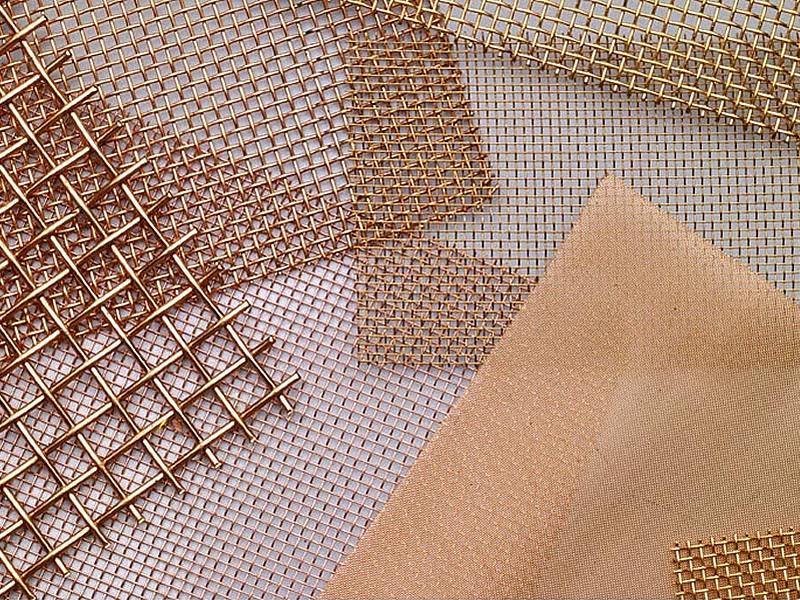

Copper Wire Mesh Is Critical to Many Industries, Woven to Industry Standard ASTM E-2006

Copper wire mesh also called copper screen or copper wire cloth, is made of pure copper, copper has excellent electrical conductivity, thermal conductivity and ductility, it is one of the popular metal products because of its super electrical conductivity malleability and flexibility making it the ideal material for electronics, electric power, communications industry and many other industries. Its non-magnetic, anti-sparking and resistant to many chemicals, salt air and brine, making it an ideal choice for salt and briny conditions. Its reddish-orange color also makes it an ideal choice in the architectural decoration industry.

The weaving method of copper mesh is generally plain weave or twill weave, and the mesh count can be up to 200 mesh/linear inch, which can be used in various industries. The standard length of woven copper mesh roll is generally 30 m or 100 ft, customers can also cut according to the actual needs of the size.

The uses of copper wire mesh include RFI and EMI shielding, gasket, window screen, gas and liquid filtration, etc.