FeCrAl Woven Wire Mesh - High Temperature Resistance

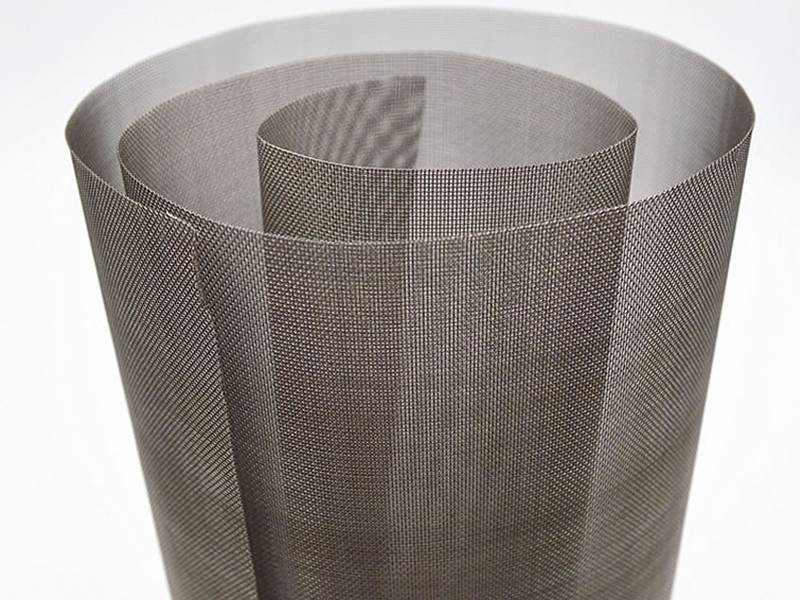

FeCrAl woven wire mesh is also called FeCrAl alloy woven wire, heating resistance alloy woven wire, electro thermal alloy mesh. The raw material is woven into a continuous meshes. Except for the FeCrAl woven wire mesh, there are FeCrAl expanded metal mesh and FeCrAl perforated metal mesh.

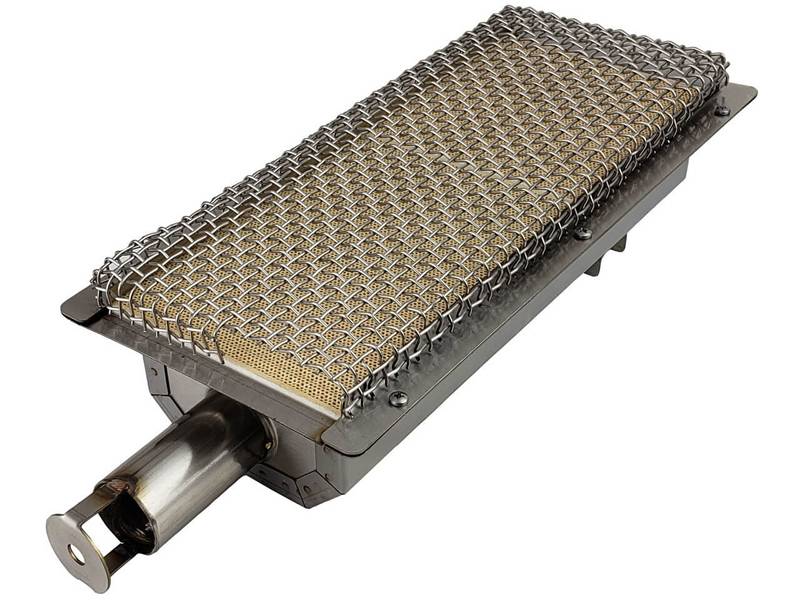

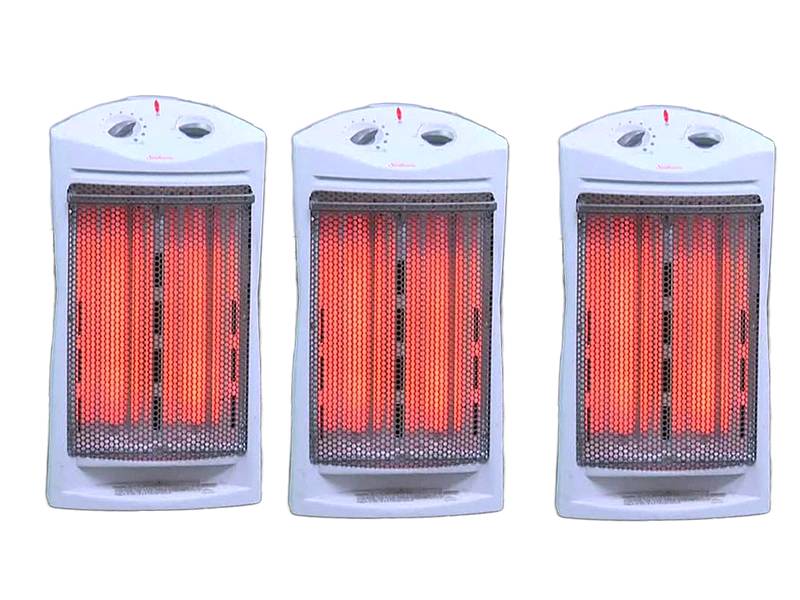

FeCrAl Wire Mesh is made of FeCrAl alloys, it has low temperature coefficient of electric resistance and exceptionally high service temperature limit. FeCrAl Wire Mesh offers resistance to attack in the wide range of corrosive media such as sulfidizing, carburizing and oxidizing media at the elevated temperatures by producing an adherent security oxide layer upon heating. By using the right material, FeCrAl mesh can work at the high temperature as high as up to 1400 °C. It is widely used in gas burners or as the carrier of catalyst on vehicle exhaust treatment device. The typical mesh form for gas burners is round disc made of woven wire mesh and for vehicle exhaust treatment device is wire mesh strips.