Stainless Steel Wire Mesh Is High Temperature and Corrosion Resistant, Is Popular Material for Industrial Field

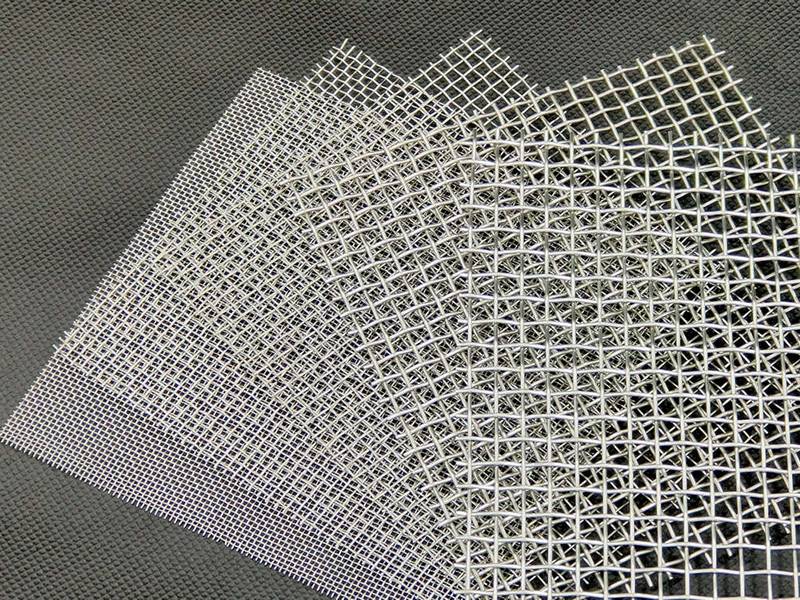

Stainless steel wire mesh is an industrial product made from interlocking metal wires, also named stainless steel woven cloth, stainless steel woven mesh, stainless steel wire netting.

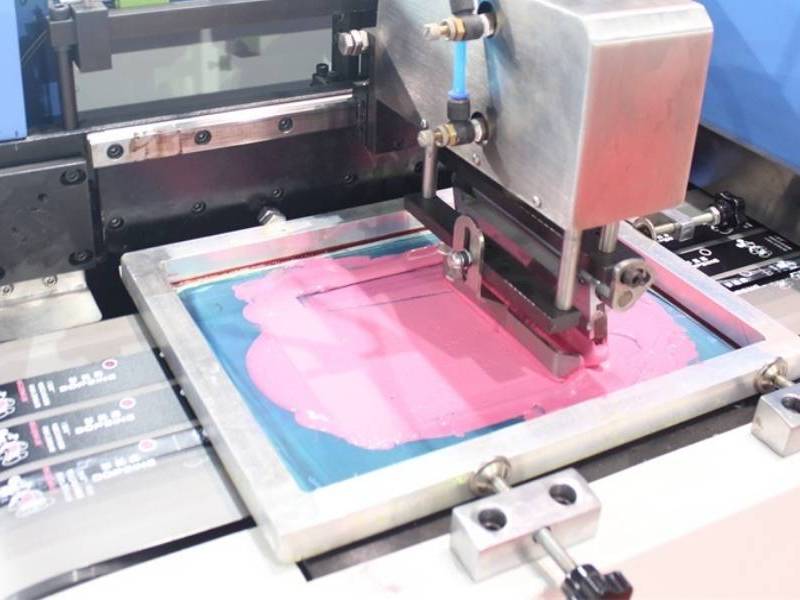

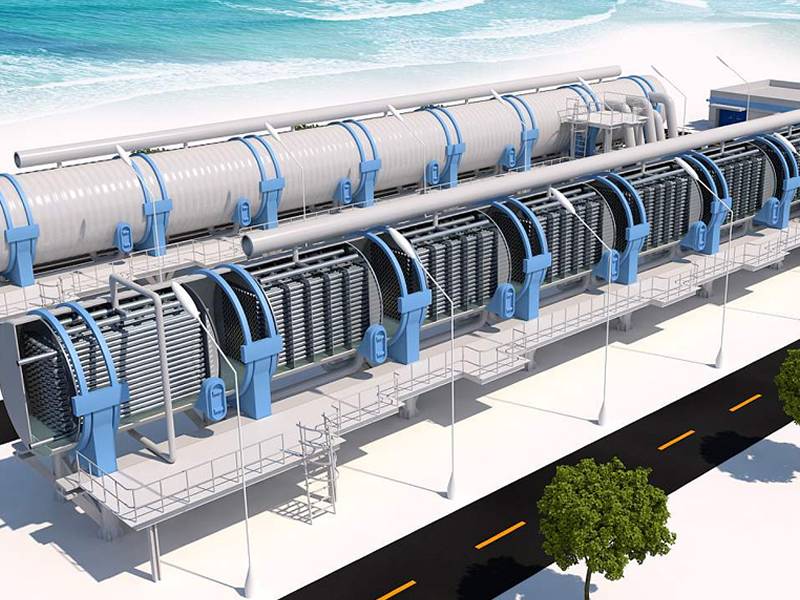

Stainless steel wire mesh, with its excellent resistance against acid, alkali, heat and corrosion, find extensive uses in processing of oils, chemicals, food, pharmaceuticals, also sorting and screening of solid, liquid and gas in mine, metallurgy, airspace, machine making, etc.