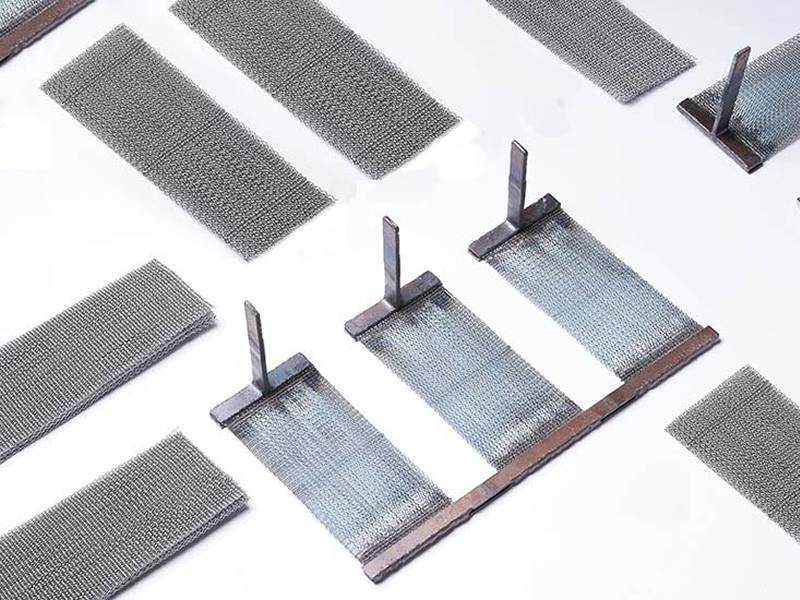

Tungsten Wire Mesh With the Highest Melting Point Is the First Choice for Heating Elements

Tungsten wire mesh is a heavy duty rare metal mesh which has the highest melting point but lowest vapor pressure in all the metal meshes in pure form.

Tungsten wire mesh is woven from pure tungsten wire, and its purity exceeds 99.9%. Tungsten is an off-white, very hard, refractory metal element that has the highest tensile strength and high-temperature resistance of any metal. After weaving into a tungsten wire mesh, it can maintain high strength even at high temperatures exceeding 1650°C and is very durable. It has extremely high thermal creep resistance, the highest use temperature up to 3410°C (melting point of tungsten).

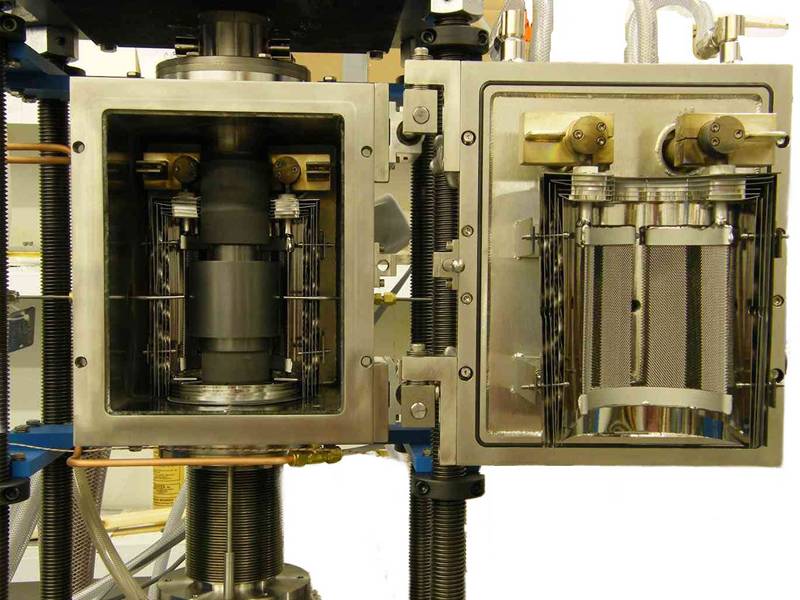

Tungsten wire mesh inherits the characteristics of tungsten, such as refractory, low evaporation rate, strong tensile strength, etc. With excellent heat resisting and high electrical resistivity, tungsten wire mesh is the preferred material for radiation shielding, heating element of vacuum furnace. Besides, it is also with high density and corrosion resistance, often used as filter or sieve materials for acid, alkali environmental conditions.