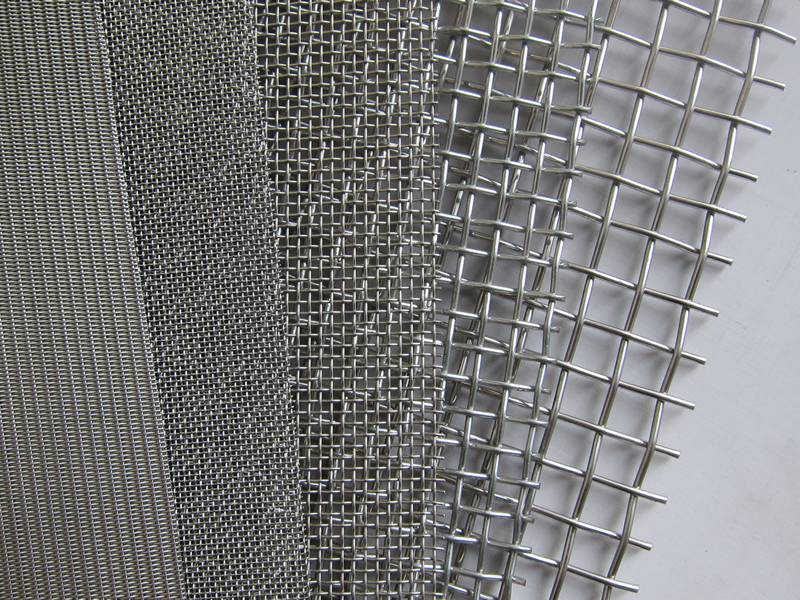

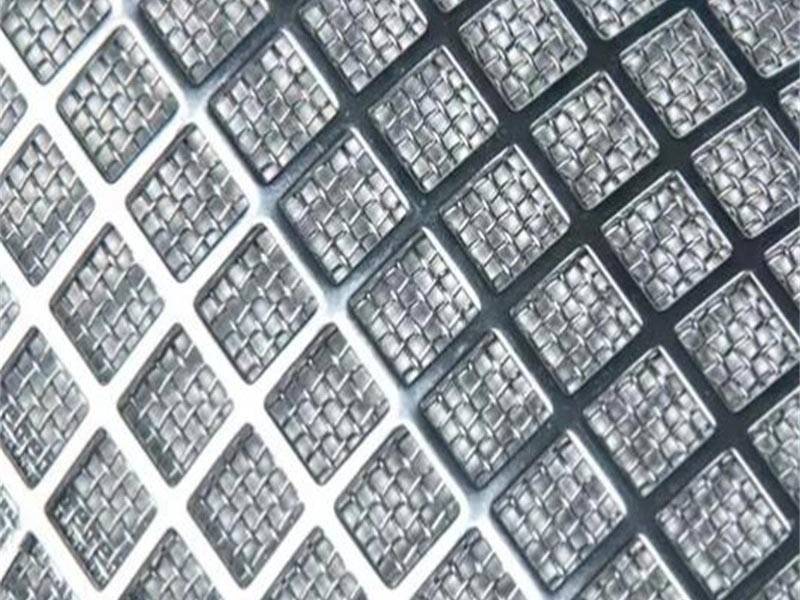

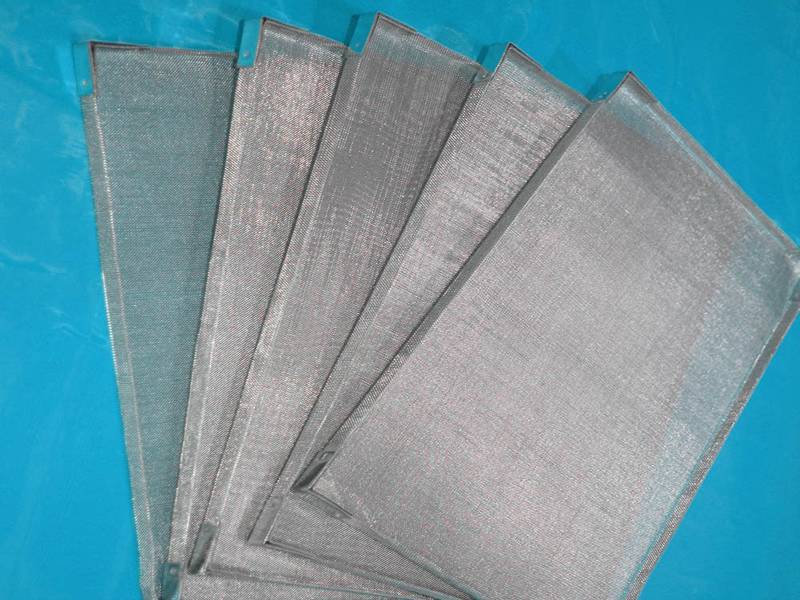

Inconel Woven Wire Mesh Made of Inconel Wire 600, 601, 625, 718, X-750

Inconel wire mesh is made of alloy wire of nickel, chrome and iron, which predominantly nickel, chromium as the second element. According to the different chemical composition content, the most common Inconel wire including Inconel 600, Inconel 601, Inconel 625, Inconel 718 and Inconel X-750 and so on.

Inconel woven wire mesh is a special type of metal mesh can adapt to extreme environments but resistant to corrosion, oxidation. Further more Inconel wire mesh is non-magnetic, it can maintain a high strength and good weld ability in a temperature range from below zero to 2000°F (1093°C). Its most typical usage including chemical fiber, petrochemical, aerospace, hydropower, nuclear power, thermal treatment, pulp and paper industry.