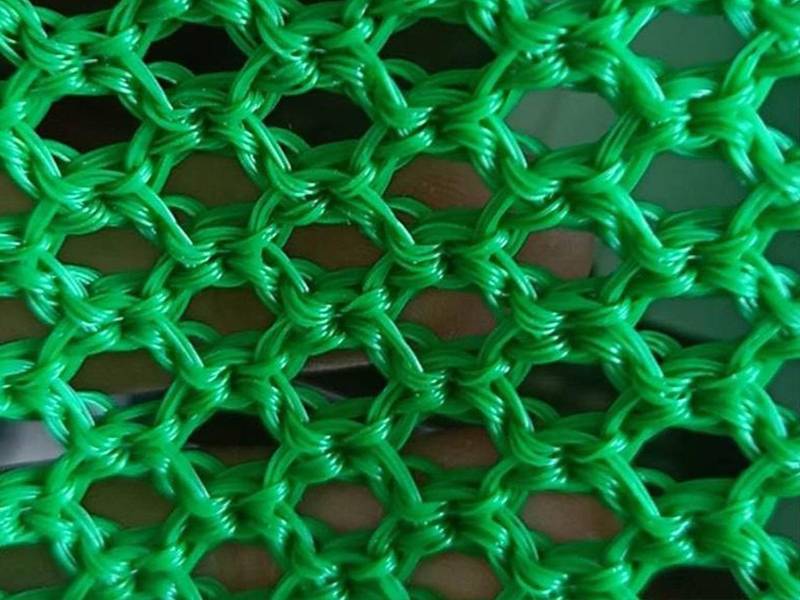

Flexible Windbreak Netting

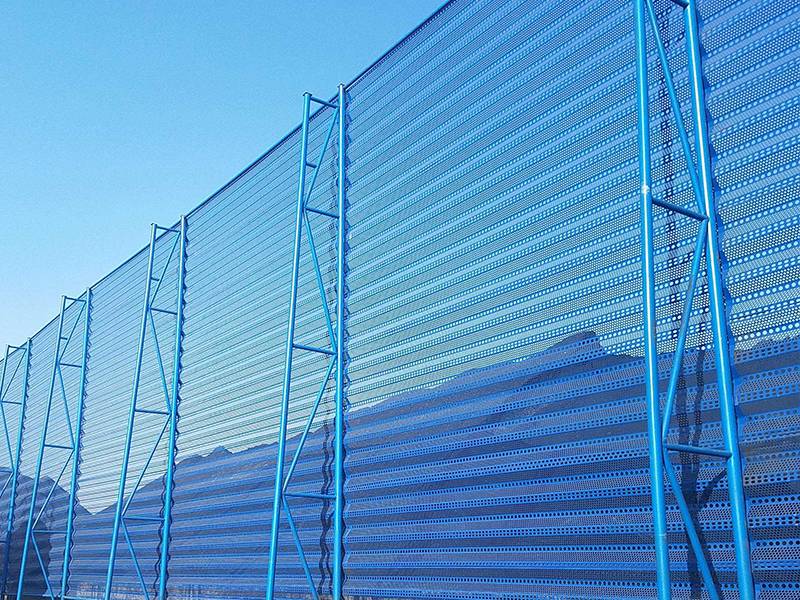

Perforated metal windbreak panel is also called the anti-wind and dust panel or sand wind break barrier, and can be installed into a wind and dust wall. A wind and dust wall is most effective to solve the dust pollution in power plants and coal mine. The dust suppression effect of the single-layer wind and dust suppression wall can reach 65% – 85%, and the effect of the double-layer wind and dust suppression wall can reach more than 95%.

The windbreak wall / wind dust fence is based on the principle of aerodynamics. According to the results of the implementation of the on-site environmental wind tunnel test, it is processed into a certain geometric shape, opening ratio and different hole shape combined wind and dust suppression wall, so that the circulating air (strong wind) passes through the wall. In the body, the upper and lower disturbing airflow is formed on the inner side of the wall to achieve the outer strong wind, the inner weak wind, the outer small wind, and the inner side without the wind, thereby preventing the dust from flying.

Perforated metal windbreak panel is widely used in many places, such as power plants, coal mines, coking plants, coal washing plant; ports, terminals and markets a variety of coal storage yard. coal storage and station of Railway and highway transportation. construction sites, both sides of the highway and dust road. crops windproof, desertification weather dust and other harsh environments, and so on.