Offshore pipeline counterweight welded wire mesh is also called concrete weight coating mesh, Pipeline reinforced mesh, is a line wire crimped special welded mesh. It plays the role of reinforcement, counterweight and protection for offshore oil and gas pipelines.

Our most commonly used line wire crimped special welded mesh specifications are mainly divided into 4 types: CT-N, CT-T, CT-L and CT-W.

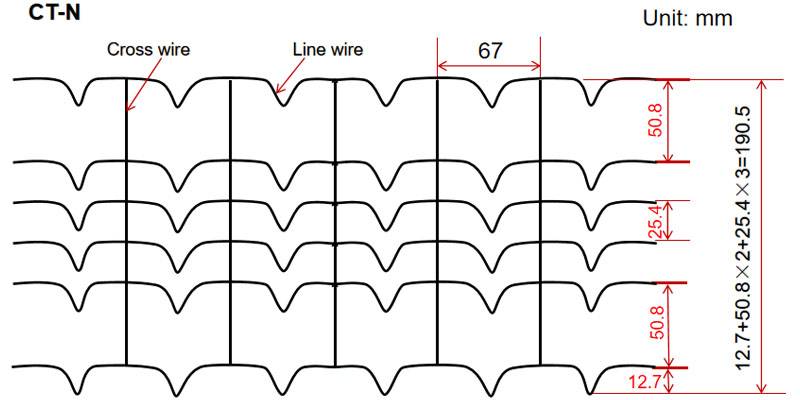

CT-N pipeline counterweight welded mesh

It is a low carbon steel wire for the reinforcement of concrete weight coated pipelines. The mesh includes 6 line wires that are deeply crimped between the cross wires. The 2-inch mesh with both sides between the line wires is intended for coating with an overlap of 1 inch.

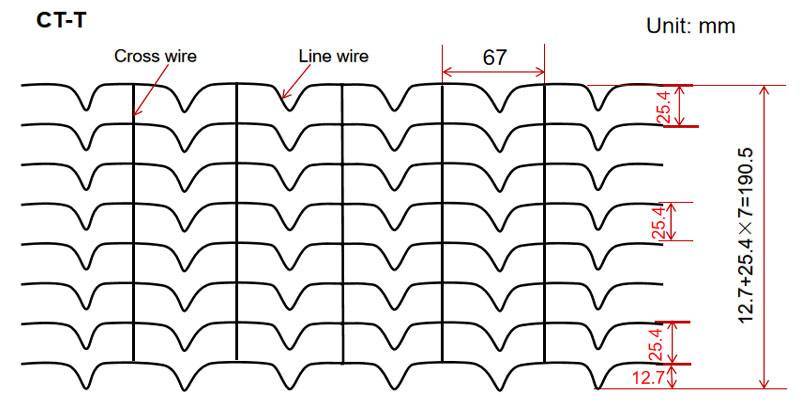

CT-T pipeline counterweight welded mesh

It is a spot welded mesh made of galvanized low carbon steel wire for the reinforcement of concrete weight coated pipelines. The mesh includes 8 line wires that are deeply crimped between the cross wires.

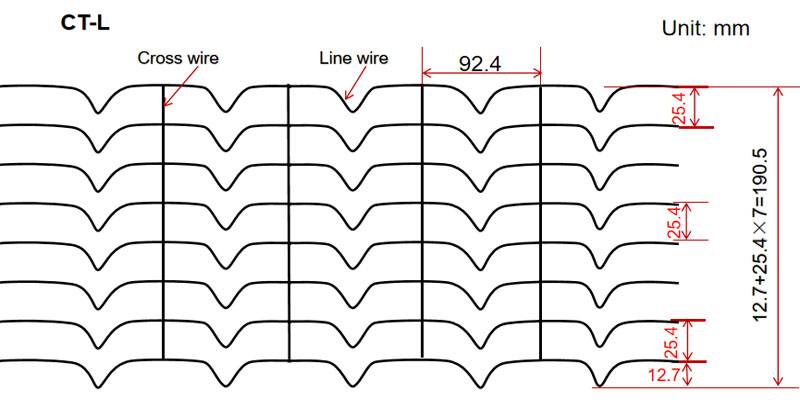

CT-L pipeline counterweight welded mesh

It is a spot welded mesh made of galvanized low carbon steel wire for the reinforcement of concrete weight coated pipelines. The mesh is 92.4 mm instead of 67 mm between the cross wires.

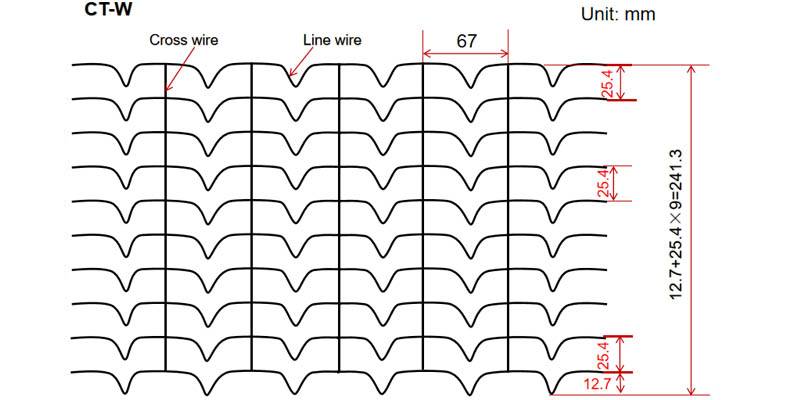

CT-W pipeline counterweight welded mesh

It is a spot welded mesh made of galvanized low carbon steel wire for the reinforcement of concrete weight coated pipelines. The mesh includes 10 line wires that are deeply crimped between the cross wires.